Urban Sector

Biogas plants fuelled by OFMSW

According to the European Directive on waste (Waste Directive 98/2008), the hierarchical order that must be given to waste management, in order from most preferred to least, is as follows:

- The waste prevention and reduction;

- Materials recycling and recover;

- Energy recovery;

- Final deposit in landfill.

In compliance with European directives, Biowaste focuses primarily on the all dry recyclable fractions recovery. From the waste’s organic fraction it’s possible to produce renewable energy and natural fertilizers, reducing the inert fraction’s that cannot be recovered conferment into the landfill .

The first part of this process concerns the chemical analysis of the waste, its possible danger determination and the the affected area framing.

Biowaste offers an integrated management system that can provide an optimal solution, exploiting available technologies and meeting the most stringent environmental limits.

We evaluate the different possible scenarios to be able to provide the most suitable solution, depending on the expected results in environmental and economic terms.

The mechanical pretreatment is the fundamental step to obtain a suitable mixture, which allows to eliminate all superfluous nonbiodegradable waste which would decrease the process efficiency. Although the achievable separation quality inevitably depends on the separate collection efficiency, Biowaste offers different mechanical treatment configurations based on the quality of the incoming waste and the degree of the implemented at the source separation: screening, iron removal, pressing, shredding and mixing.

The innovative, reliable and versatile machinery use allows us to optimize investment costs and to increase energy yields. The most suitable way to maximize organic waste is the combination of anaerobic and aerobic treatments (anaerobic digestion and composting). The biogas produced during the fermentation process is a totally renewable and sustainable high quality fuel, while the obtained from the aerobic treatment compost is a fertilizer material used for agricultural uses. If performed in series, the cycle tends to close with significant economic benefits and environmental.

OFMSW BIOGAS Plant

We develop unique and innovative technical solutions for the OFMSW through anaerobic digestion treatment.

Installing a OFMSW plant's advantages

The non-reusable fractions minimization, thanks to an ad hoc pre-OFMSW treatment line;

Absence of impurities, paper and plastic materials, thanks to the OFMSW squeezing system;

Miximization of energy production deriving from organic matter's anaerobic digestion;

Biowaste's technology digesters against the aggregates deposit and the foams formation;

The digestate's liquid fraction purification to discharge into the surface water body;

The natural compost production thanks to the leaving from the fermenters digestate sent to the aerobic treatment;

Low electrical and thermal consumption;

Fully developed insourcing technology.

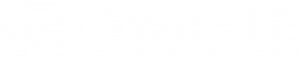

How is a biogas plant powered by OFMSW made?

The OFMSW pretreatment:

- Bag opener;

- Dynamic screening;

- Magnetic metal separator;

- Squeezer.

- The load pre-tank with diluition and sand removal;

The liquid fraction separation and purification:

- Helical separators and centrifugues;

- Biological purification plant with possible membrane section and evaporation for the concentrate reduction and discharge into surface water or into sewer.

Composting of the solid fraction of the digestate mixed with the green

Odor treatment line

Energy section from biogas use to generate:

- Biomethane for transport or to be placed on the network;

- Electricity;

- Heat.