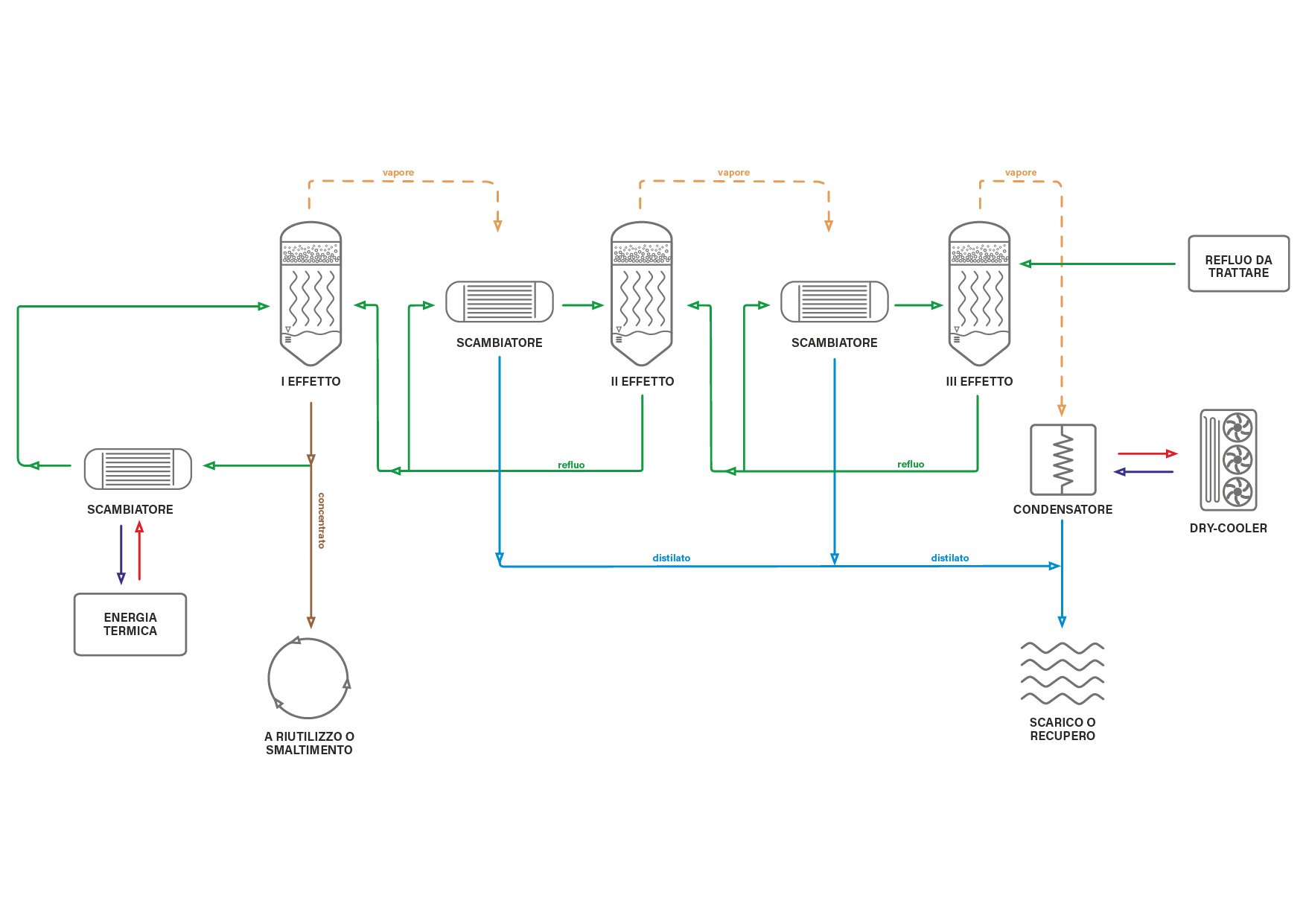

Impianti di Evaporazione

L’evaporazione è il processo che per ebollizione di una soluzione elimina parte del solvente e realizza la concentrazione della soluzione stessa. È applicabile per trattare reflui industriali, anche con matrice molto complessa, in cui possono essere presenti sostanze inquinati sia di natura organica che inorganica, purché poco o per niente volatili.

Viene impiegata quando tecniche di trattamento alternative più economiche non consentono di conseguire risultati soddisfacenti, al fine di ottenere un effluente idoneo allo scarico o al riciclo interno.

A fronte di costi d’investimento e di gestione che ne fanno uno dei sistemi di trattamento delle acque reflue più onerosi, a meno che non sia disponibile energia termica di recupero, esso garantisce rese molto elevate, perché permette di ottenere la massima percentuale di acqua depurata e la minima quantità di concentrato finale (rispettivamente fino al 90-95% di distillato e 5-10% di concentrato).

Diverse tipologie di evaporatori e diverse varianti di processo sono state sviluppate per tenere conto della differente natura delle soluzioni da trattare, della resa di evaporazione richiesta, del tipo e costo delle fonti di energia disponibili.

Le tipologie di evaporatori sottovuoto che Biowaste può proporre sono:

- EVAPORATORE SINGOLO O MULTIPLO EFFETTO AD ACQUA CALDA O VAPORE

Questa tipologia di impianti viene impiegata quando si ha a disposizione energia termica a basso costo, ottenuta:- Bruciando il biogas generato nelle discariche;

- Utilizzando l’acqua calda prodotta dal raffreddamento dei motori e/o dei fumi di scarico dei cogeneratori;

- Recuperando il calore presente nelle altre acque di raffreddamento utilizzate all’interno dell’azienda.

- EVAPORATORE A RICOMPRESSIONE MECCANICA DEL VAPORE (MVR)

- EVAPORATORE A POMPA DI CALORE

Per queste due tipologie di impianto non è necessario disporre di energia termica, in quanto il funzionamento avviene esclusivamente mediante assorbimento di energia elettrica. In particolare, per la ricompressione meccanica del vapore il consumo è compreso tra 40 – 50 kW/t di acqua evaporata mentre sale fino a 150 – 200 kW/t per gli impianti a pompa di calore.

Uno dei fattori che maggiormente incide sul costo di investimento degli impianti di evaporazione è il materiale di costruzione delle parti a contatto con la soluzione da trattare. A seconda della sua composizione, del pH e della temperatura di esercizio dell’impianto, si possono utilizzare:

- AISI 316 L (1.4435)

- AISI 316 Ti (1.4571)

- Duplex 904 L (1.4539)

- SAF 2507 (1.4410)

- Grafite o PVDF

Sempre in funzione delle caratteristiche della soluzione da trattare, vengono impiegati scambiatori di calore del tipo a:

- A piastre;

- A fascio tubiero orizzontale o verticale;

- A superficie raschiata.